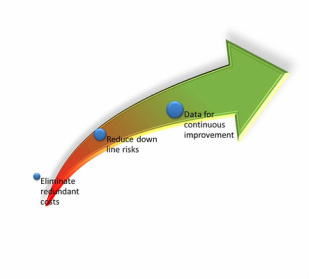

The Big PictureVision systems, when properly applied, benefit our clients in the ways seen at left:

- Eliminate redundant labor, setup and scrap costs - Reduce the risk of adding value to a scrap part - Provide data for the continuous improvement loop

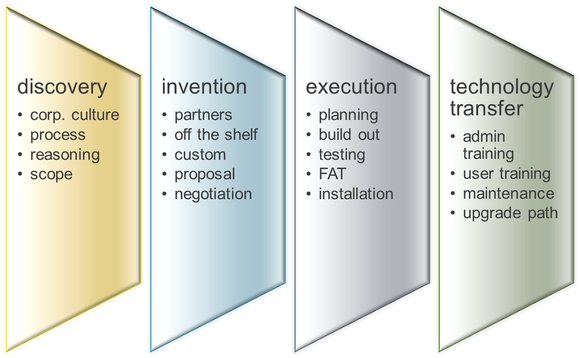

The acronym we use for our development process is D.I.E.T.

- Discovery, creating a complete assessment - Invention, devising a robust solution - Execution, implementing the solution - Technology Transfer, educating the client on its use |

Machine vision is a widely accepted technology in the realm of modern factory automation. Another common name for this descipline is "automated optical inspection".

Vision systems use vision software that extract target information from acquired images. Specialized machine vision lighting and hi-resolution lenses enable the cameras to measure features of interest to great accuracy.

These systems commonly provide information to guide robots, identify high-value products, provide dimensional gauging data and perform surface inspection.

These tasks are typically performed at high speeds and in high quantities. These vision systems can and should be periodically validated as part of a validation system.

Vision systems use vision software that extract target information from acquired images. Specialized machine vision lighting and hi-resolution lenses enable the cameras to measure features of interest to great accuracy.

These systems commonly provide information to guide robots, identify high-value products, provide dimensional gauging data and perform surface inspection.

These tasks are typically performed at high speeds and in high quantities. These vision systems can and should be periodically validated as part of a validation system.

The paper below describes a number of facts on error-proofing and cost reduction using machine vision

Your browser does not support viewing this document. Click here to download the document.

Our expertise as a "vision integrator" includes the following: inspection, guidance, identification, gauging,vision inspection, vision gauging, vision identification, vision guidcnace, turnkey, programming, validation, testing, automation, factory automation, Cognex, Keyence, cognex vision, keyence vision, "automated optical inspection" and dimensional inspection.